Sancliff stands as a true industry leader, surpassing the conventional role of a die manufacturer. Our steadfast commitment to leveraging the latest and most advanced technology empowers us to produce a diverse range of products entirely in-house within the United States. This capability not only underscores our dedication to quality and precision but also positions us as a versatile and reliable partner for our clients.

By harnessing the power of cutting-edge technology, we at Sancliff have unlocked a world of possibilities for our customers. Whether it’s the development of intricate dies, precision tooling, or specialized components, our in-house manufacturing capabilities enable us to deliver exceptional results with uncompromising efficiency and quality.

Die Craftsmen Since 1948

WE ARE THE DIE GUYS

Optical Fiber Coating & Coloring Dies. Shaped Wire Dies & Fiberglass Strength Member Production Dies.

Certified & Recognized By

Trusted & Quality Assured

Celebrating 75th Anniversary (1948 - 2023)

World's Best Die Manufacturer

Sancliff Inc. - Die Craftsmen Since 1948

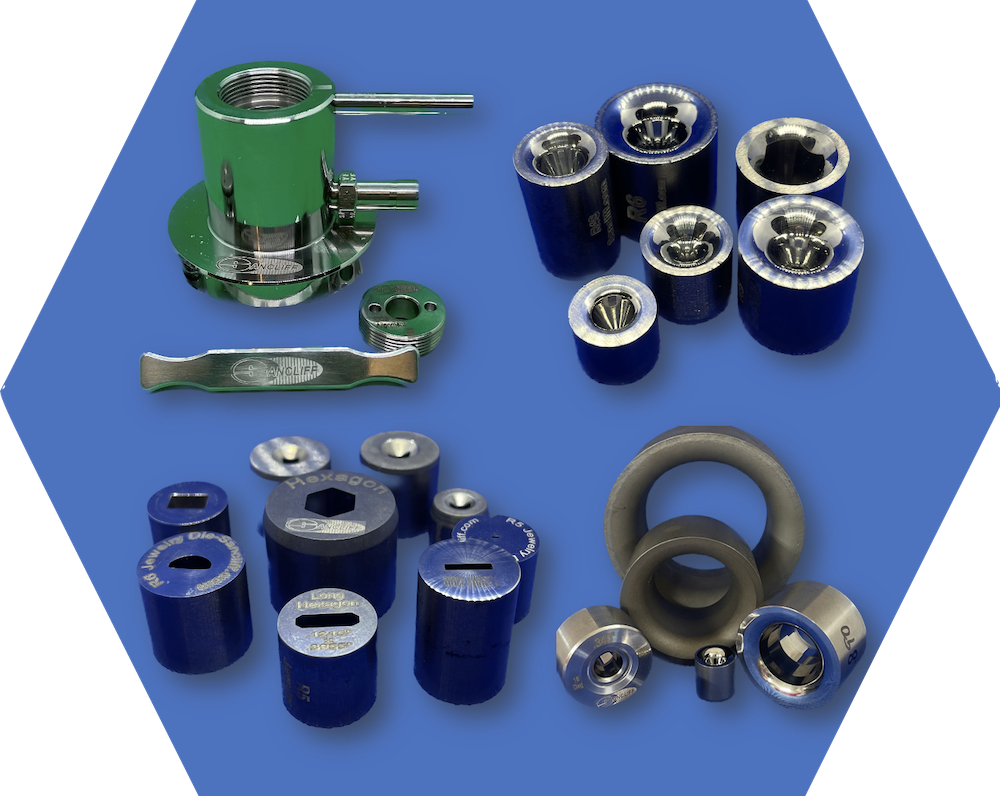

Sancliff offers a vast array of products, from the simplest drawing die to the most complex optical fiber coating systems and much more! Partnering with Sancliff will give you the competitive advantage that is needed on todays market!

Sancliff Inc. was founded in 1948 by 2 gentlemen, Sanford Kelleher & Clifford Flanders, forming the company Sancliff as yet to be incorporated. They began operations in Jefferson, Massachusetts as a wire die manufacturer & material supplier to the then vast Worcester county Wire manufacturing industry.

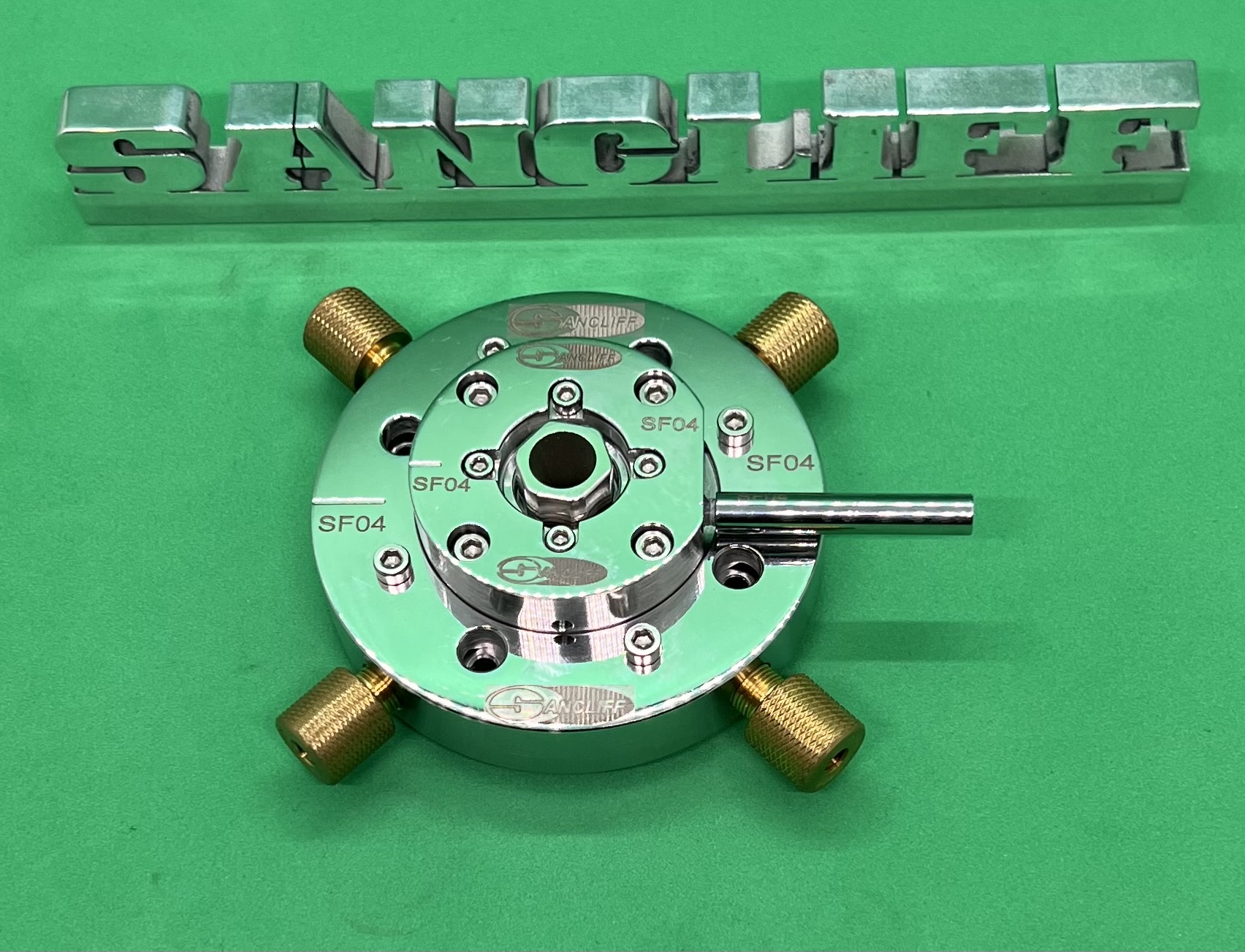

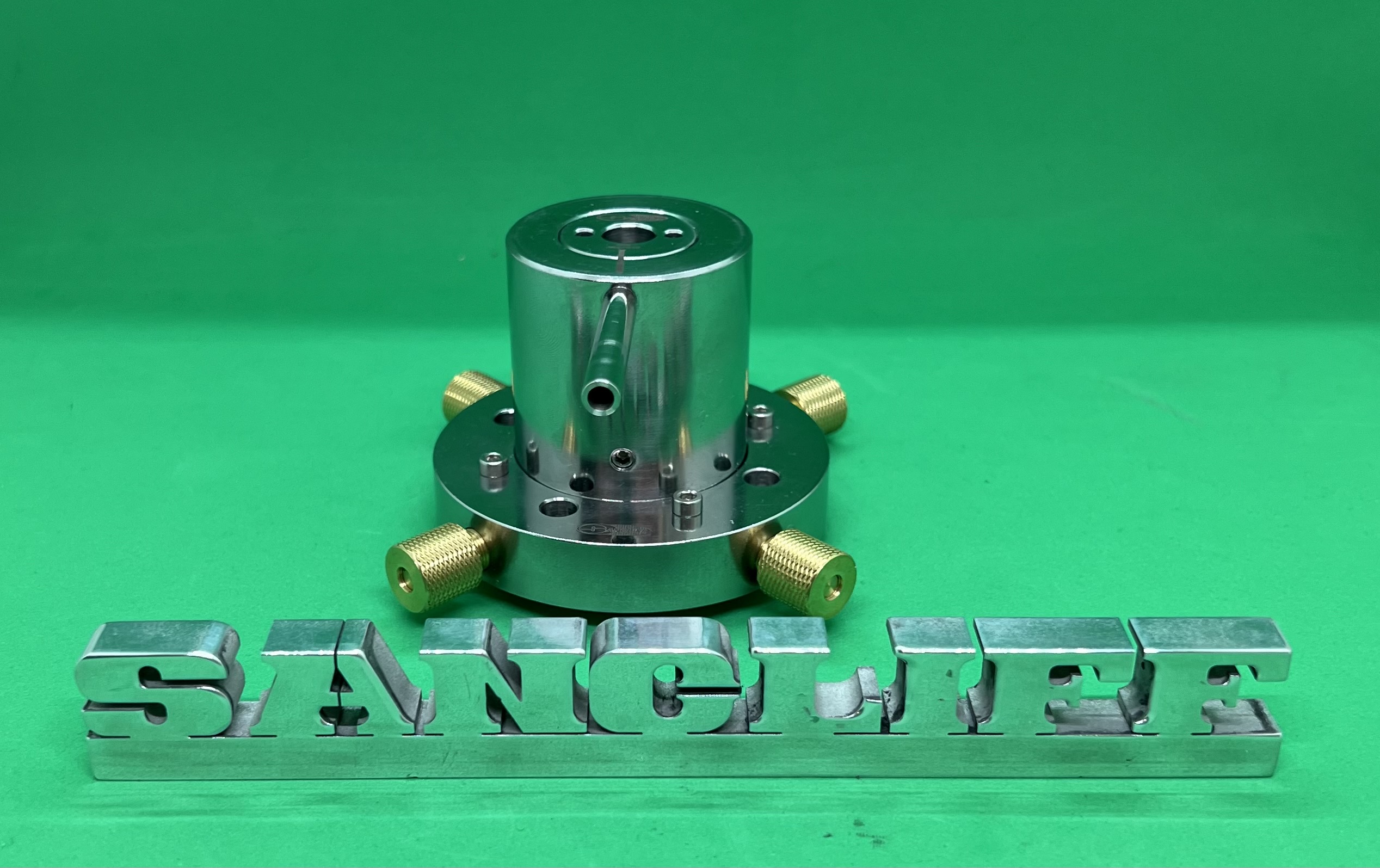

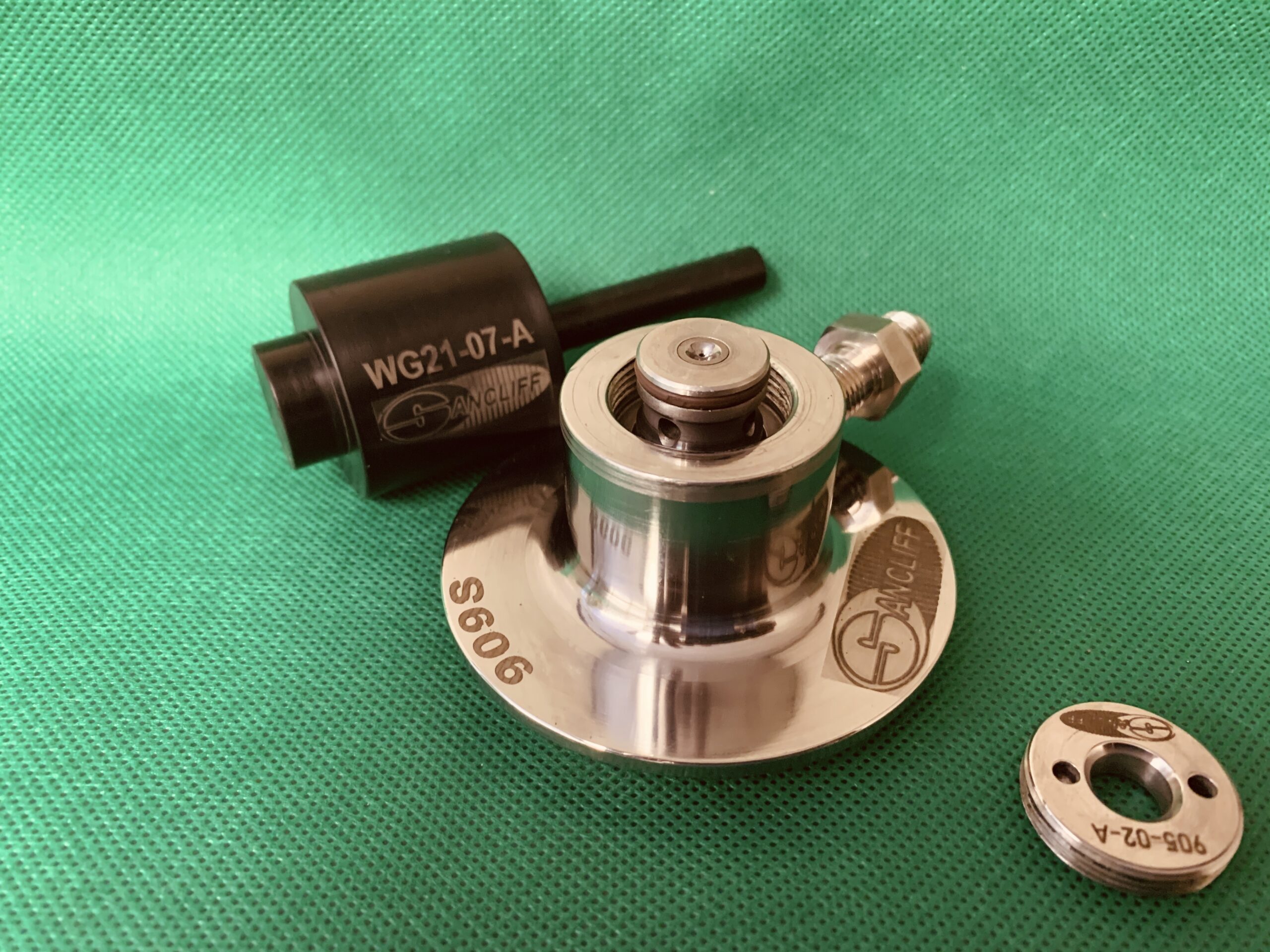

Optical Fiber Coating & Coloring Dies

Optical Fiber Coating Dies , Fiber Optic Coloring Dies, Ribbon Coating Dies & Applicators

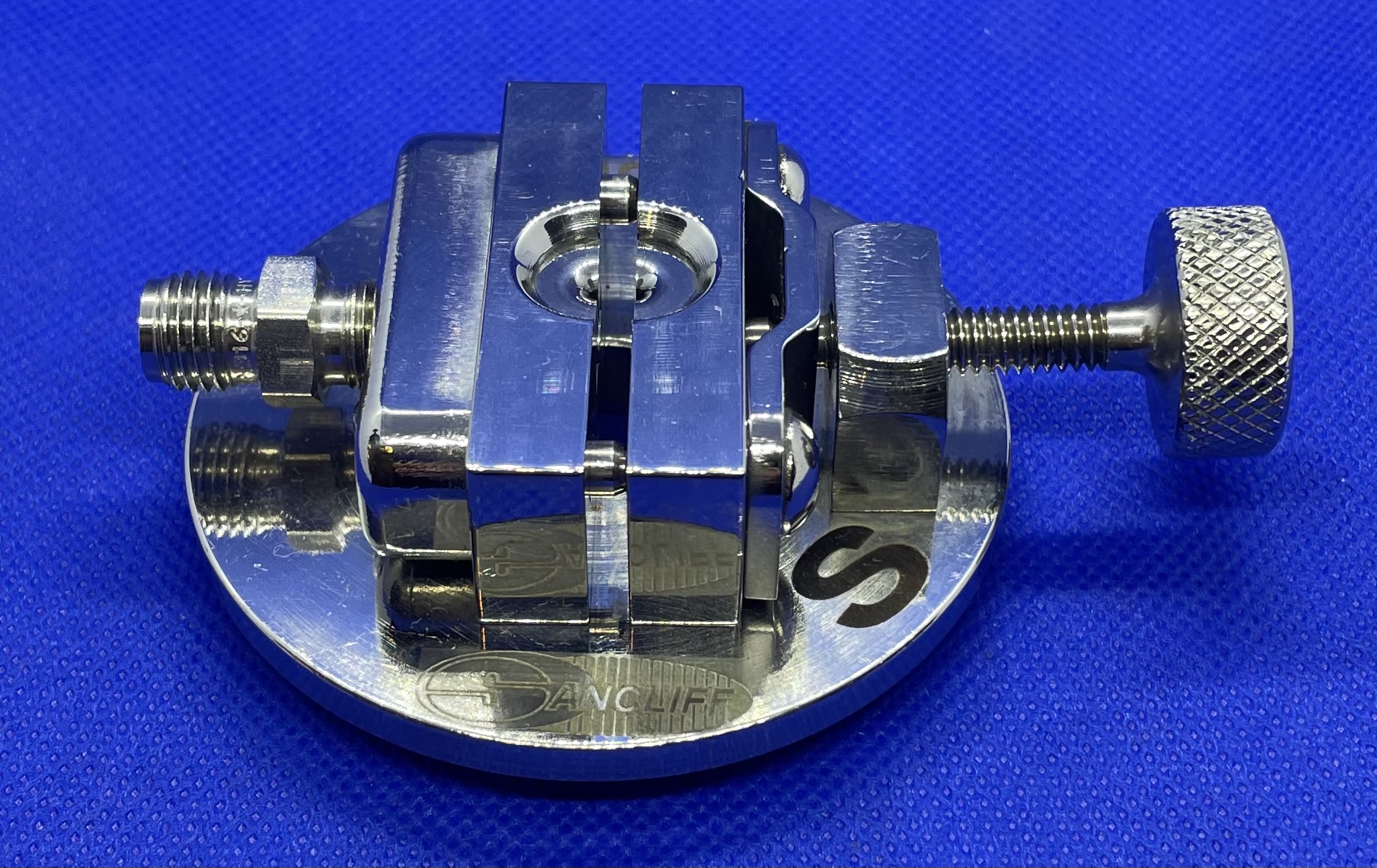

Sancliff Optical Fiber Coating Dies, Coloring Dies, Ribbon Forming Dies, Coating Head Assemblies, and Pressurized Coating Systems are engineered to deliver controlled supplies of diverse viscous chemical compositions to our Optical Fiber Coating Head and Die Assemblies. All Sancliff manufactured Optical Fiber Coating, Coloring and Cladding devices are available in split, solid, wet on wet, twin and multi configurations for conventional round and/or specialty shaped fibers and substrates.

Fiberglass & Textile Dies

Fiberglass Strength Member, Textile Coating & Impregnation Dies

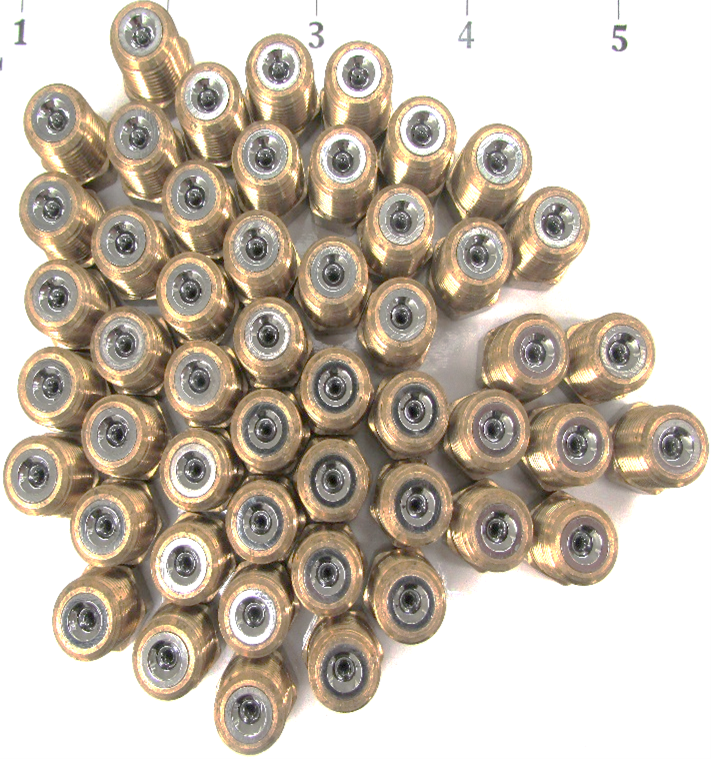

Fiberglass Reinforcing strength member Dies & Textile coating dies are manufactured from the finest Sub-Micron Grain size Tungsten Carbide with the tightest possible geometric specification tolerances available. Sancliff has been designing, specifying, and supplying standard and custom dies to the textile & fiberglass strength member, fiberglass screening & Sun Protection fabrics manufacturing industry for more than 73 years. Our Tungsten Carbide coating dies are in constant use in all parts of the world and we count on many of the world’s top fiberglass reinforcing member & fiberglass textile manufactures as our valued clients.

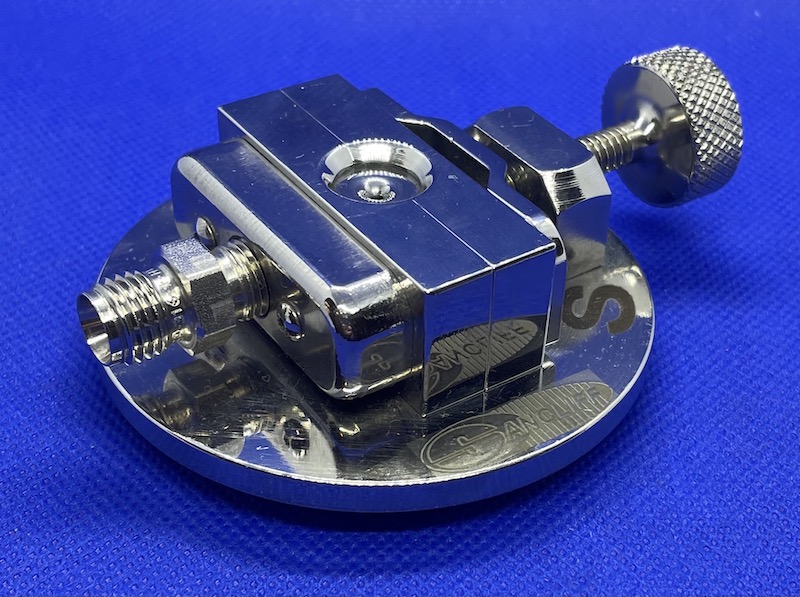

Tungsten Carbide Round & Shaped Wire Drawing Dies

Tungsten Carbide, PCD, ND, Round & Shaped Wire Drawing Dies & Tapered Drawing Inserts

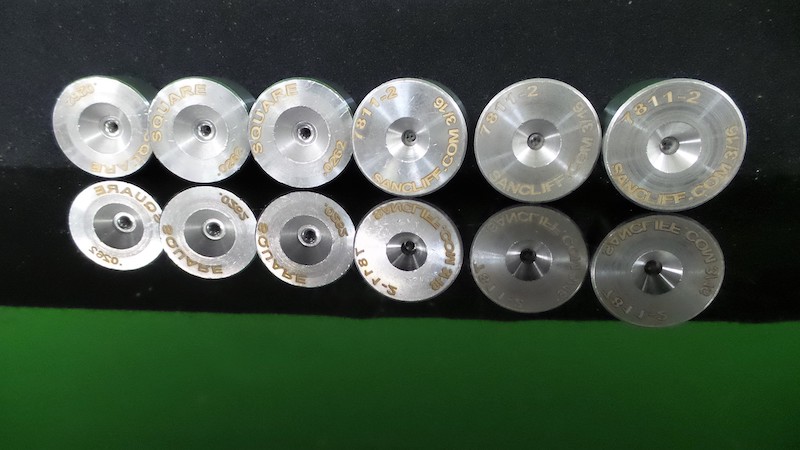

Sancliff was founded as a Tungsten Carbide Wire Die Manufacturer in 1948. Sancliff Round and Shaped Wire Drawing Dies are made from the finest virgin Tungsten Carbide materials available. These materials combined with Sancliffs 73+ years of die design, Manufacturing and real world application & functionality experience allows Sancliffs talented team of engineers, designers & toolmakers to create the finest Round & Shaped Wire Drawing Dies of unparalleled quality, consistency and value. Our historically short lead times constantly exceed customer expectations. We offer new Tapered Drawing Inserts, conventionally cased wire drawing dies, Shaped Dies, recuts & so much more.

We Are in Action

Watch Our Videos

508-795-0747

Phone Support Available 8AM – 4:30PM EDT

sales@sancliff.com

Email Support Available 6AM – 4:30PM EDT

Visit us

97 Temple Street, Worcester, MA 01604

Need A Quote? Contact us Today.

Here at Sancliff we are continually improving and updating our equipment in order to provide you with the finest products on the market. We’d love to assist you. Let’s talk soon.